SPD’s policy has always been to satisfy the needs of the customer.

The organisation has always evolved both in terms of turnover and in terms of quality and, today, is a sure point of reference in its field. It operates nationally and internationally. Customers are contacted either directly or through a network of higly qualified agents and representatives. The organisation’s production is divided into two levels: standard products and special products, studied and designed on the basis of specific customer requirements; this is why, the company has two designing offices (mechanical and electronic) with a large number of qualified resources and advanced designing tools.

The organisation now has a head office with an adjoining warehouse for finished products and three local units dedicated to production. Within the organisation, roles and responsibilities are well defined and structured to ensure effective and efficient management.

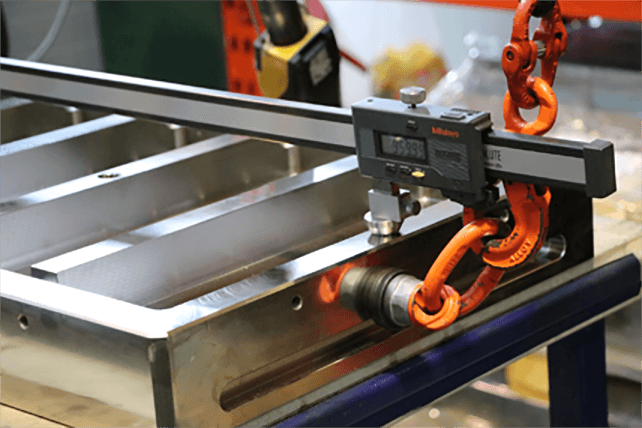

The focus on customer satisfaction is also reflected in the quality controls performed at the beginning and the end of the production cycle.

All components ordered to third parties as outsourcing are controlled by one or more qualified operators (input controls). The control sampling ranges from 20% (for standard products) to 50% (for special products) and uses the most modern portable measuring instruments on the market.

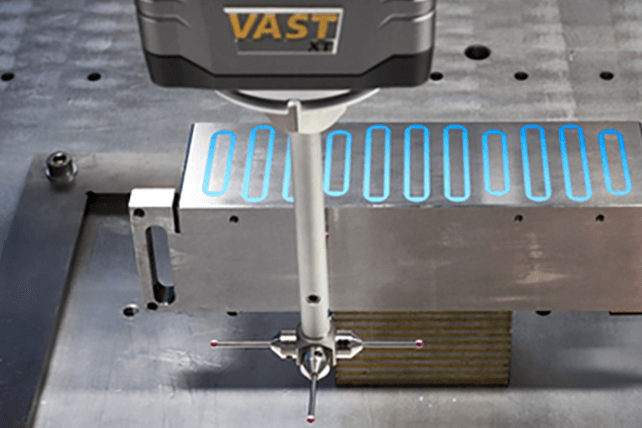

All products manufactured internally, once completed, are checked by one or more qualified operators (output

controls). In the main production unit, the company has set up a control area containing coordinate measuring machines of different brands (Zeiss, Ethalon, Faro).