The quick mould changeover system for presses represents, thanks to the electro-permanent technology, the most efficient way to reduce the required time to change the moulds and to simplify clamping operations, avoiding any efforts for the operator.

ADVANTAGES

OPTIMAL CLAMPING

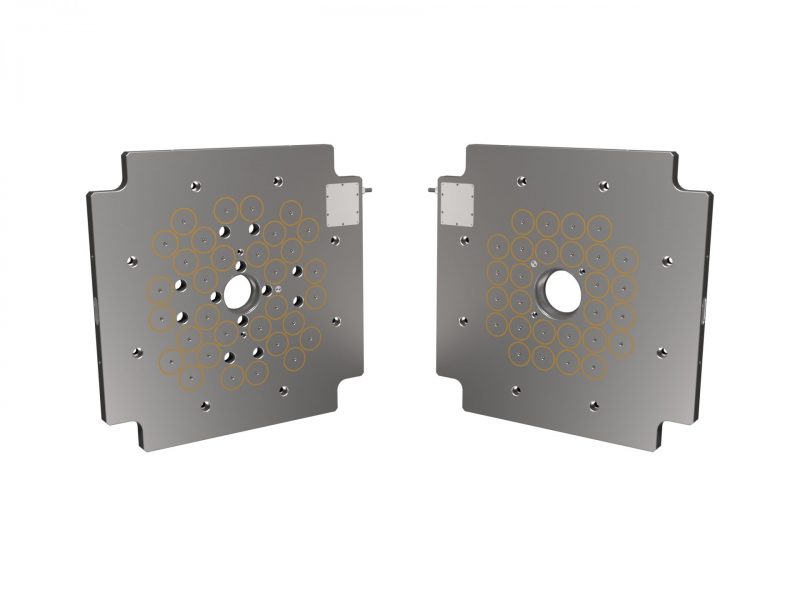

The magnetic system SYMPLI -T, unlike conventional clamping systems, generates a clamping force which is evenly distributed over the entire surface of the mould sub plate, thus avoiding any tension and deformation.

VERSATITLITY

The SYMPLI-T system can be adapted to all types of presses provided with threaded holes or “T” slots, thus allowing the use of the entire available surface of the press plates.

UNIFORMITY

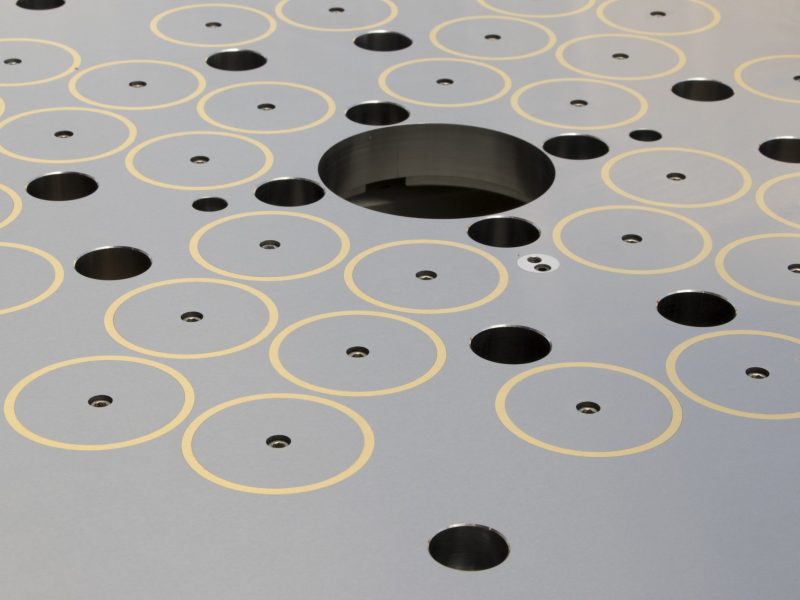

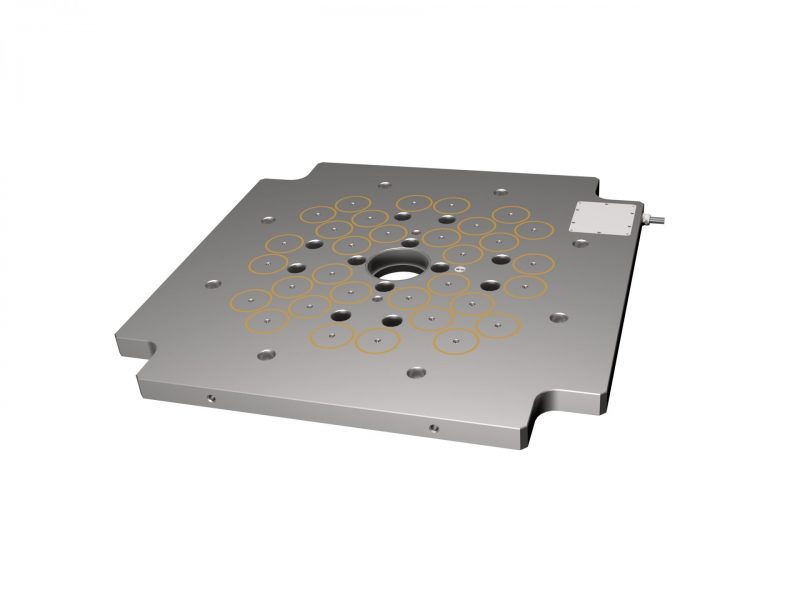

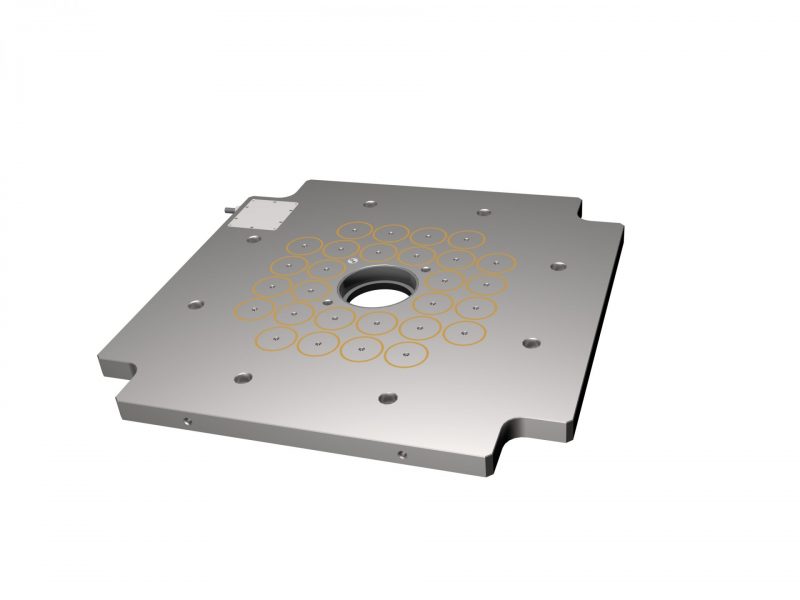

The magnetic chessboard structure of the SYMPLI-T module provides an extremely uniform clamping force on the surface, facilitating consequently its versatility.

STURDINESS

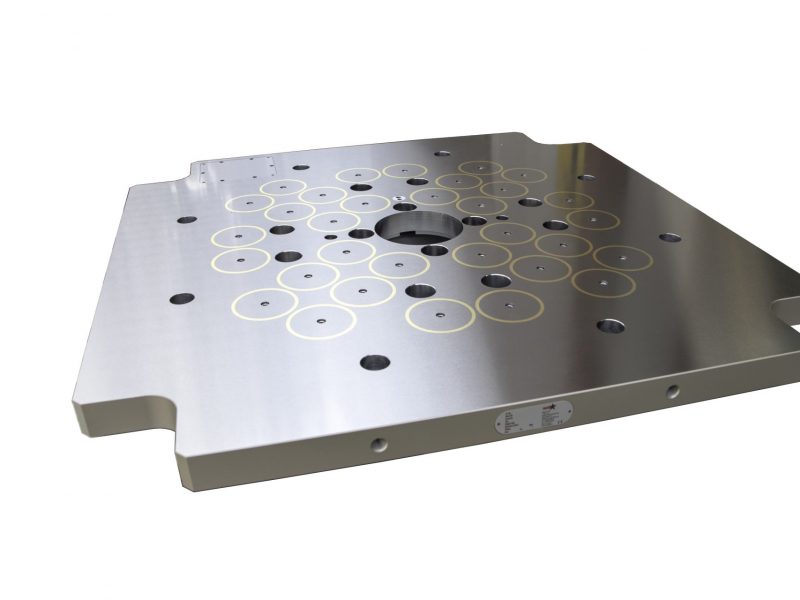

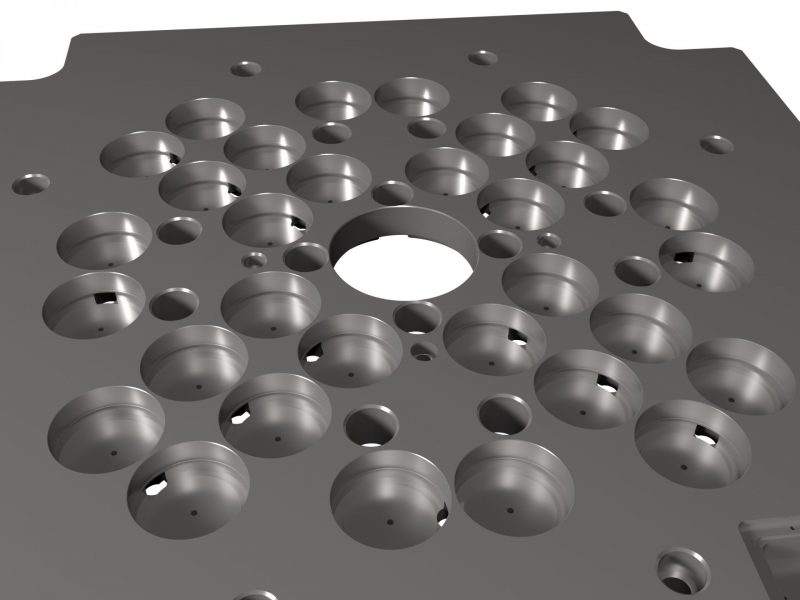

SYMPLI-T modules offer very high mechanical resistance as they are obtained by machining a single steel block. The chuck surface is made of iron and brass to better withstand stress, wear and tear and operating temperatures, requiring at the same time less maintenance.

SPEED AND EASE

The SYMPLI-T system considerably reduces mould change times and simplifies clamping operations, avoiding any efforts for the operator.

FEATURES

ACTIVE MONITORING

If the mould is detached by more than 0.2 mm in the automatic mode, the press movements will immediately stop. In addition, the integrated sensors enable the system only if the mould is correctly positioned on the magnetic module.

CENTRINGT

The standard centring system allows a precise and fast positioning of the mould.

ELECTRICAL JUNCTION BOX

The built-in electrical junction box, ensures maximum sturdiness.

FIXING HOLES

The fixing holes are designed according to EUROMAP /SPI/ JIS standards, allowing the magnetic modules to be clamped onto the press tables.

THROUGH-HOLES

Through-holes are provided on the movable side of the magnetic module upon customers’

request for the ejector rods.

ROUND MAGNETIC POLE WITH INSULATING BRASS RING

Thanks to the use of round magnetic poles it is possible to optimise the clamping force of the mould, regardless of its shape. The insulating brass ring ensures a better resistance to strain, wear and tear and to high operating temperatures.

INSTALLATION

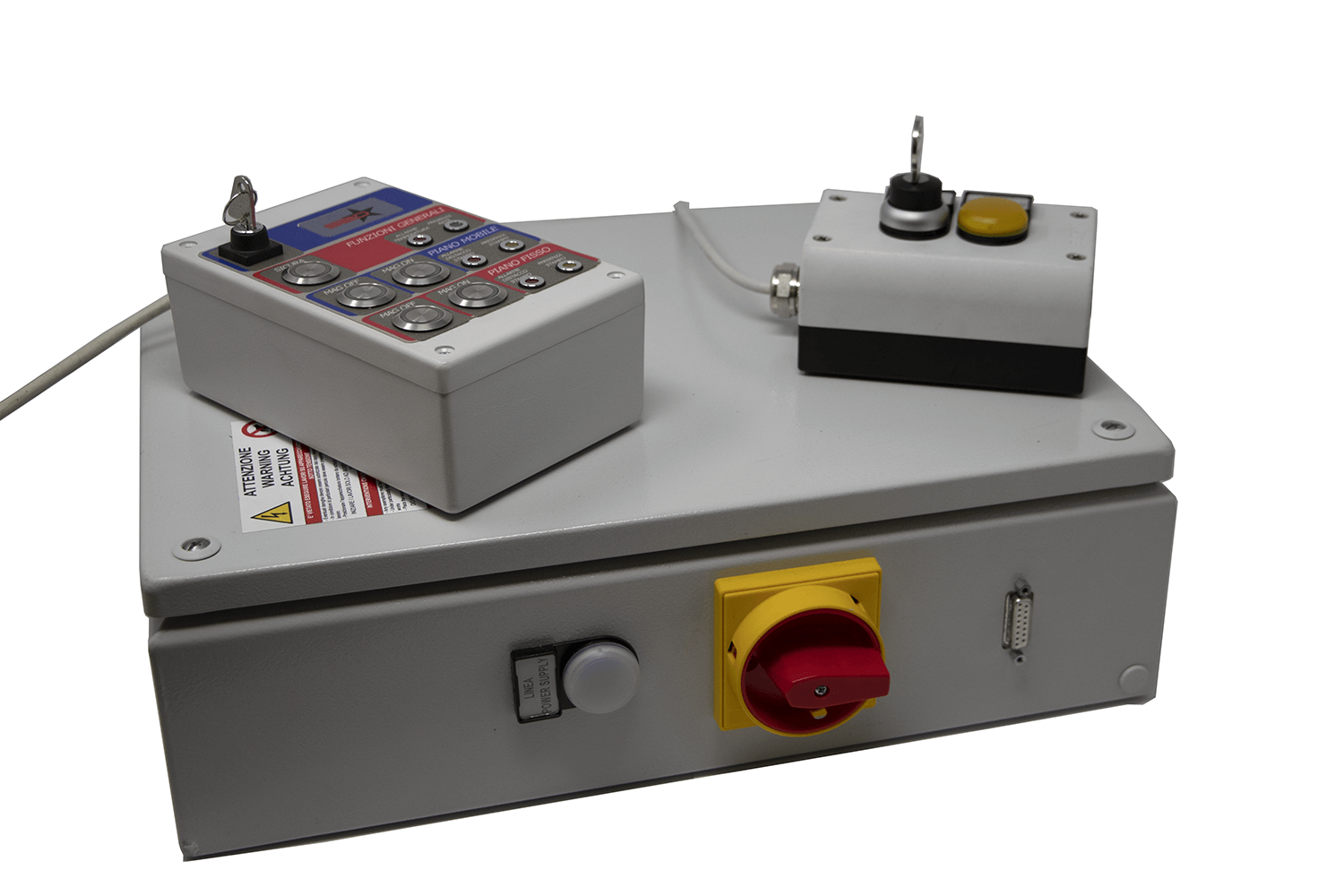

The electronic control unit features devices ensuring the safety of both operator and material. The enabling key on the remote control prevents unauthorised personnel from using the system. The simultaneous use of the safety and the MAG On and MAG Off buttons prevents unintentional activations/deactivations. A device measuring the magnetic saturation level, on the other hand, always guarantees the highest possible performance.

The SYMPLI-T system features furthermore an innovative digital system for measuring the magnetic flux, in order to know the magnetic force of the clamped mould under all conditions. An efficient and state-of-the-art numeric calculation algorithm is able to analyse the signals captured by an array of solenoids integrated inside the magnetic surface, which provides a completely noise protected force value thanks to an intrinsic computational stability.

The SYMPLI-T system is operated remotely from a control panel including all the operational functions and indicating the various system conditions. More specifically, the operator receives the information from the panel of any possible mould detachment or of an excessive temperature reached by the magnetic module. Finally, it provides all the interface signals necessary for a perfect integration with both modern and retrofit presses. Its main feature is that it doesn’t enable the production start unless the mould is correctly positioned and magnetized.